Progress Update – Thursday, November 6, 2025:

The production of our new title continues to advance with precision and care. Each stage of the process — from printing and binding to the finishing of materials — is carried out by specialists whose craftsmanship gives the book its distinctive physical quality.

In Bremen, the decorative stripes for the covers of the standard edition are currently being applied by silkscreen printing. At the same time, in Celle, the industrial bookbinder has sewn together the by now folded sheets into book blocks. As of today, November 6, all book blocks for the limited special edition of 964 copies have been thread-sewn — the correct technical term — as well as all book blocks for the standard edition, limited to 1,600 English, 964 German, and 260 French copies.

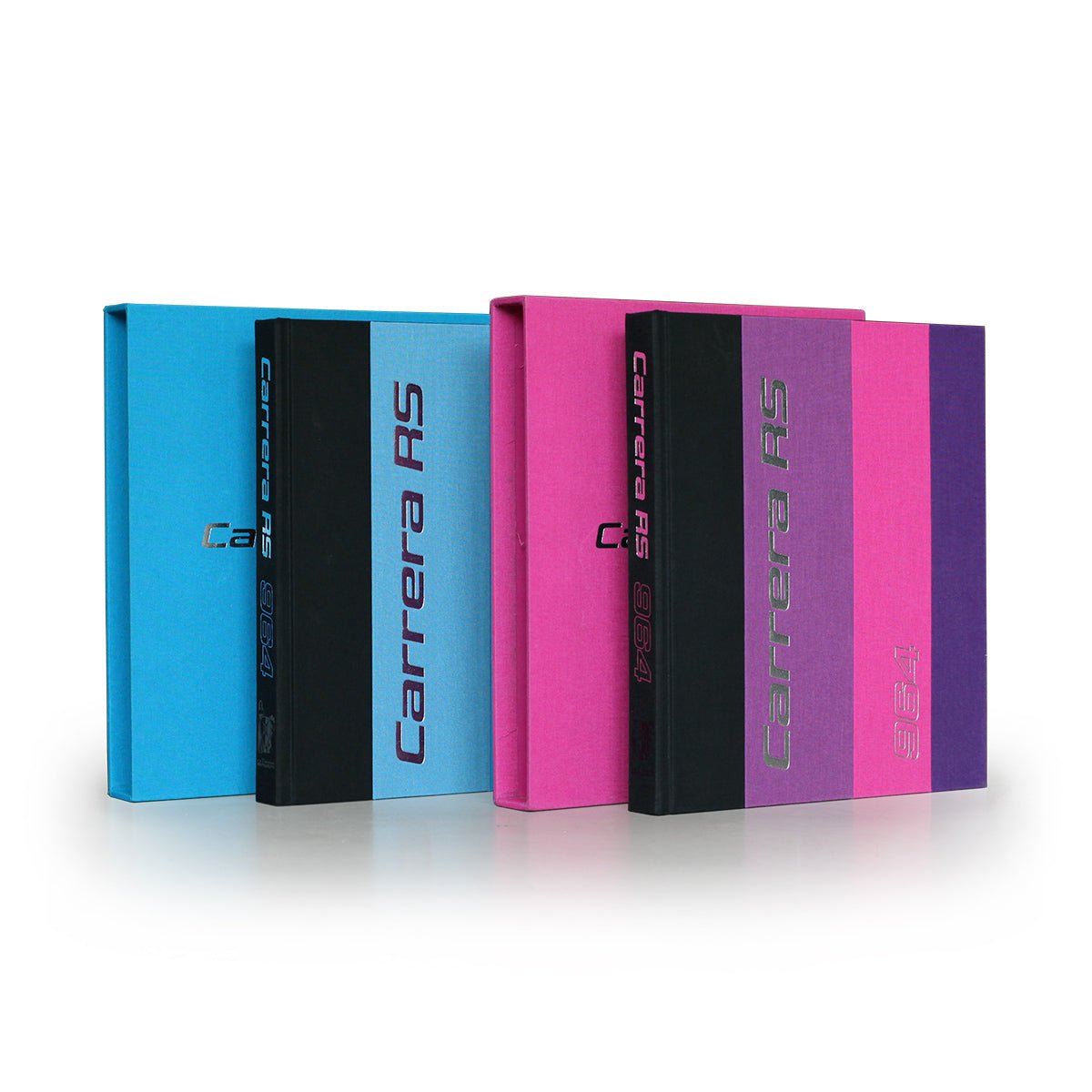

The black cover material, reminiscent of Alcantara, receives three decorative stripes. To ensure the colors achieve their full intensity, each stripe is first underprinted in white — slightly narrower than the final color layer. Three further printing passes follow for the English edition in Old Rose, Rubystone Red, and Violet; and another three for the blue-toned variant in Light, Medium, and Dark Blue. Once set up, the screen-printing machine operates at roughly 500 sheets per hour. In this process, ink is drawn across the mesh with a squeegee, the screen’s density measured at 100 threads per centimeter.

Silkscreen printing machine in Bremen

Inside Production: From Screen to Binding Line

Wherever the photosensitive layer of the screen is hardened by UV light through the film masks (see photos), it becomes impermeable. The remaining areas of the photosensitive emulsion are washed out, allowing the ink to pass through the open sections of the mesh in the next step. Each sheet carries six impressions — that is, six cover panels — printed simultaneously. After the ink is drawn across the screen, the sheets pass through a hot-air dryer at 75 °C.

At the industrial bookbinder in Celle, the 16-page sheets are first pre-creased and then folded precisely to size. During collation, the machine must be continuously fed with these folded sections in the exact sequence — hence the “sample sheet” hanging from a line above the workstation, serving as a visual guide. Once stacked in order, the sections move on to the thread-sewing machines. In this phase, three machines run in parallel, each supplied in perfect rhythm with the still loose, but correctly stacked sheets. In the thread-sewing process, each section is gently opened and stitched together with thread. As of today, all book blocks have been fully thread-sewn and are awaiting their next stage on the bookbinding line.

The bookbinding line is the largest machine in the entire production chain. Here the spines are glued, headbands attached, ribbon markers inserted, endpapers fixed, and finally the blocks cased-in — joined, glued, and pressed into their covers. This moment is comparable to the “marriage” in automobile production, where the body and powertrain come together. Before reaching this stage, 964 book blocks are set aside and transported to the bespoke book binder, where they will be transformed into the limited special edition.